Nowadays, industries are great powers regarding the development of the Country and the economy, generating jobs and offering several other benefits to the environment in which they are inserted. However, even today, many companies face certain difficulties when it comes to automating industrial processes or even coming to a consensus on which decision should be taken, because they do not have an overview of processes and production indicators. To prevent this from happening, it is essential that the industry has properly automated processes. This is valid for large, medium and small companies.

By automating the processes (and we remind you that any industrial process can be automated), the industry ensures greater agility and control over the tasks to be performed. In this article we will address some points to help industries that want to improve internal processes and ensure greater profitability and ease in their daily routine.

What is process automation?

Process automation refers to the use of tools (such as BPM) with the objective of bringing control benefits to the operational processes of a company, thus automating several manual activities. The automation of processes aims to increase the productivity of a given task, reduce operating costs, and increase performance, generating advantages for the company. Get to know more on how to implement a Process Automation tool.

What are the main difficulties faced by the industries?

When industries emerged, they operated in such a way that workers did not have a sequential and defined work process. They were simply instructed to perform any task on their own. However, in 1914 this vision of individual work was replaced by the implementation of semi-automated processes in industries, which facilitated the work process, turning it sequential, consequently accelerating production and processes.

Over the years, several ways to automate processes and digital tools were created, helping companies and allowing access to the system from anywhere, so that the task can be performed, reducing a process time from months to days.

Read more: How to identify and manage production bottlenecks?

How to solve these difficulties?

We already know the biggest problems that industries are facing for not having their processes automated. Knowing this, how can we facilitate and automate processes for the industry?

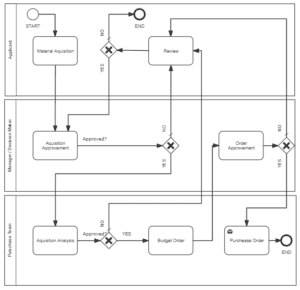

Practical example of a process that can be automated through a BPM platform:

Purchase flow:

- Applicant request a material to be purchased, and send it to the manager approvement, after the approvement, the applicant send it to a member of the purchasing team;

- Purchasing department analyses the requisition, generate a purchase order and send it thought e-mail to a supplier;

- Suppliers must answer the email that was sent to them informing the delivery time and the total budget;

- Again, the detail information provided by the supplier is forward to the company decision maker;

- The proposal is analyzed and approved or not;

- If the order is approved, the purchasing team will notify the supplier to release the material

- After the material is delivered, the process cycle will be completed and the applicant will be informed that their material is available.

This entire purchase request process can be performed automatically by BPM tool. Involving all the departments and the suppliers, keeping track of all the steps and providing real time updates. It is possible to automate ANY process.

What are the benefits obtained

Standardization of industrial processes

The standardization of processes promotes several benefits for business management. The reason for standardizing tasks is to perform each activity with repeatability, thus resulting in efficiency and quality of work. An example of a platform that performs the standardization of processes is the Fusion Platform, through which it is possible to standardize all processes of your company teams.

Loss reduction

The benefits of automating business processes are directly linked to low failure rate during the process and low rates of loss of both material and capital. With process automation it is possible to count on the same structure. After all, deviations, expenses and waste are minimized with the correct use of the tool.

Increased productivity

With the help of the tool and automated tasks, employees do not need to “waste time” making calls, sending emails, and attaching copies of files. Just perform a few simple steps and leave the rest to the tool. This means that the process becomes faster and more uninterrupted. The direct consequence is increased productivity and decreased time spent.

In closing

Automation tools deliver several benefits to the users and directly involve the performance and productivity of the company. These were some of the points raised that can optimize the processes in your company. If you are still in doubt about whether or not to invest in a BPM platform, we recommend our article Checklist: Is it time to invest in BPM? Bring your company to the digital transformation!